Rolex Bread Moulds

Rolex offers a wide variety of Bread Mould & Toast Mould, having international quality complying to globally set food safety norms and automation precision standards, and the great news is that they are manufactured & made available domestically, at affordable prices. These can be customized as per your needs and requirements.

Request A QuoteBread Box Types

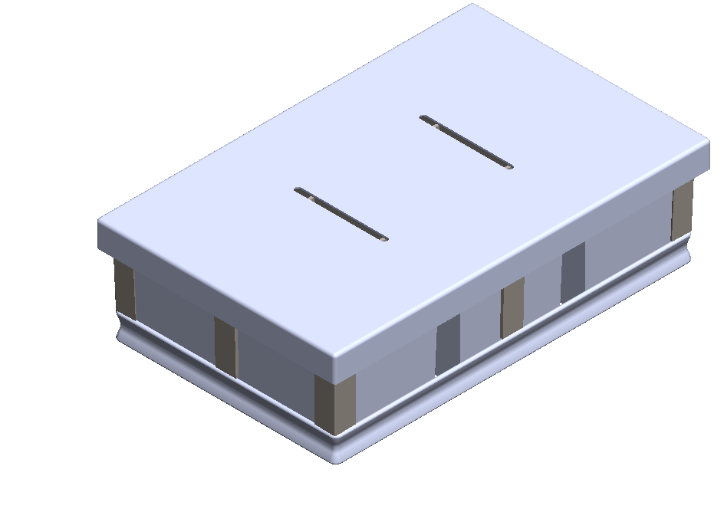

- There are two types of Bread mould manufacturing process Rolex will follow.

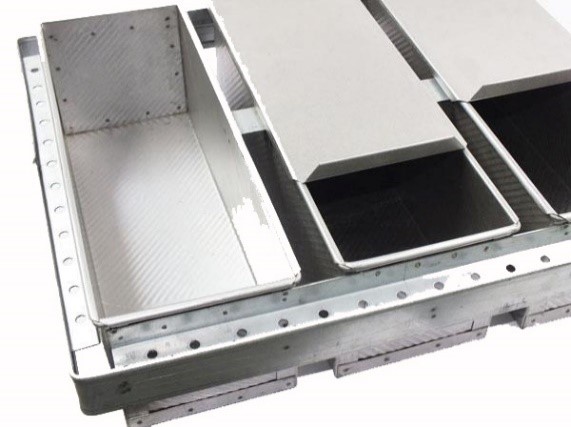

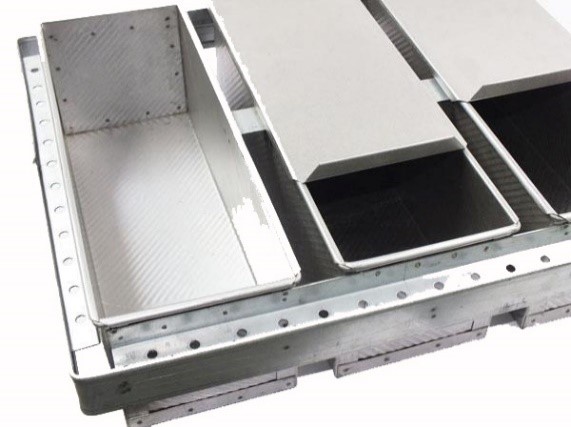

1. Fabricated Bread / Toast Box:

The Bread Mould Box was manufactured by using combination of two or more Sheet Metal Pieces. The Fabrication process decreases the cost of bread mould as it better utilizes the raw materials and also uses the Rolex standard process dies & tools. As the boxes are spot welded it provides clean sharp edges for great looking baked breads and also makes them robust for vigorous use. They are easily customizable to your size and needs.

-

Reduced cost of the box as it better utilizes the raw materials and also uses Rolex’s standard process dies & tools.

-

As the boxes are spot welded it provides clean sharp edges for great looking baked breads and also makes them robust for vigorous use.

-

Can be easily customized to suit any size or need.

Click the image to view full size

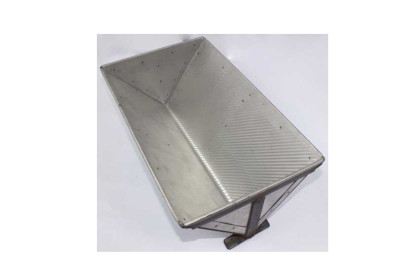

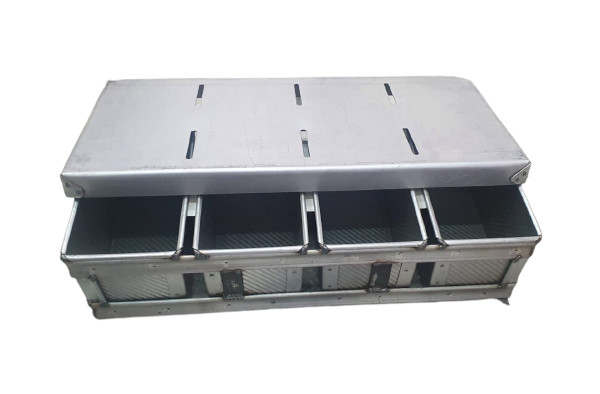

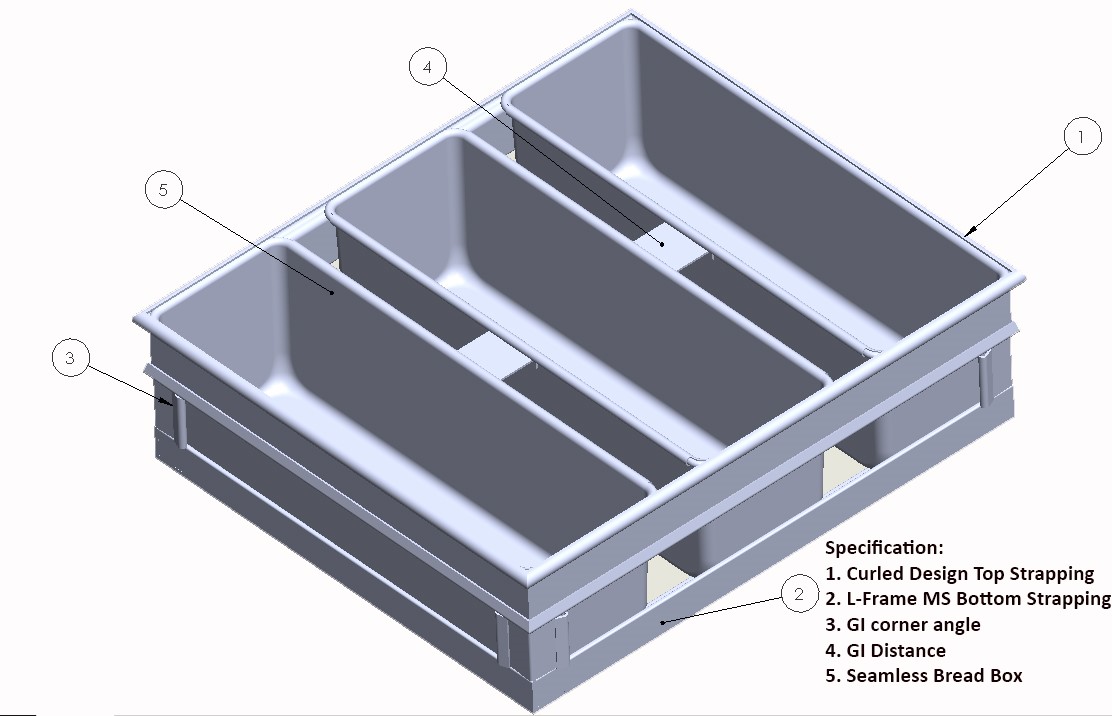

2. Seamless Bread / Toast Box:

The Bread Mould Box is manufactured from a single piece of sheet metal. The seamless bread box offers great size consistency, better heat conductivity, very easy release, reduced greasing and is also leak proof. The box is great for automations and standardizations. Since they are made from a single piece of sheet metal, they are very durable. The boxes can be manufactured as per your size and requirement.

-

The seamless bread box offers great size consistency, very easy release, reduced greasing and is also leak proof.

-

Seamless box designs are great for automations and standardizations.

Bread Mould Customisations / Specifications

Corrugated Bread Box has a series of parallelly bent rows that look like waves when seen from the edge. The corrugations increase the strength of the sheet metal, adding more strength to the bread box overall. The corrugations trap air-pockets between the dough and the metal itself reducing the surface area of contact, which aids in better heat conductivity, makes it easy to release of the Bread and also gives the bread a great color, crust and design making it look more attractive to a consumer and make your bread stand out from your competitions. Boxes available with corrugation and without corrugation for both seamless & fabricated box types.

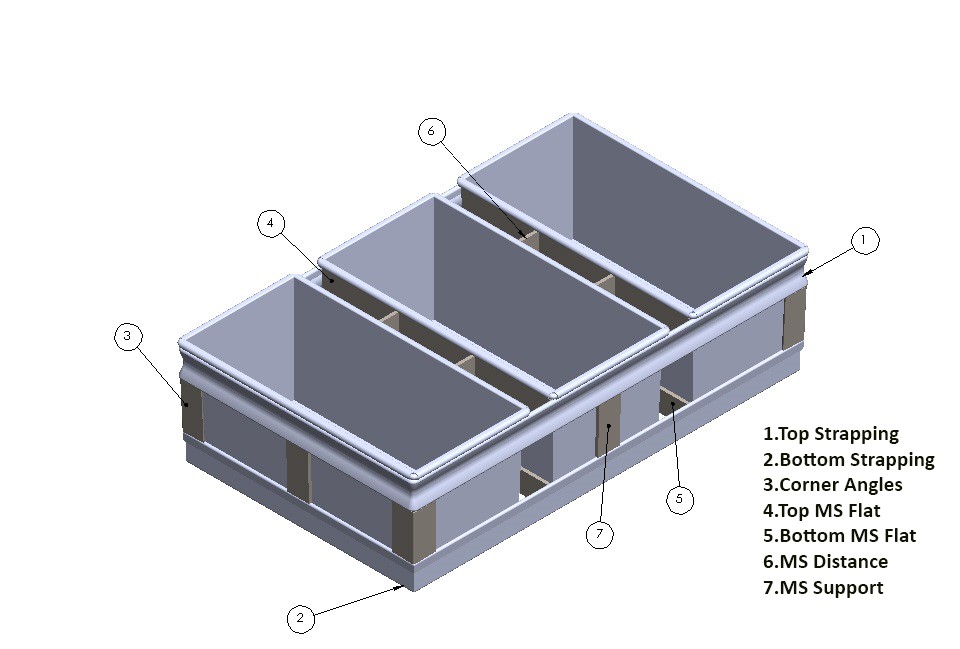

Strapping is a sheet metal strip which is folded and pressed on both edges. The strapping is used to hod together the bread box in multi-pocket arrangement.

- They provided solid rigidity to the bread mould set which gives strength against shock, accidental drops and during day-to-day handling.

- Strappings are directly welded to the bread box at the wire corners, hence keeps the boxes secured and prevents them from dislodging during heavy usage and depanning

- Strapping provides support to the top as well as bottom of the set.

- Strappings are customizable to your size and needs.

1. Top Strapping:

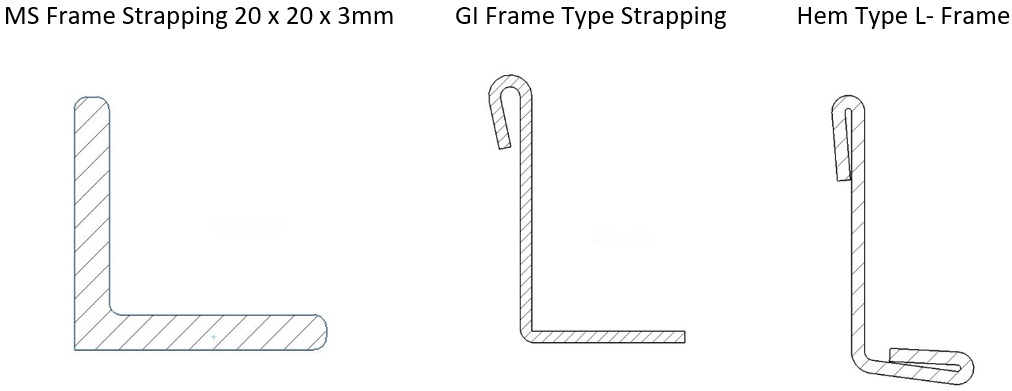

Rolex has multiple top strapping designs for the varying needs of consumers.

- Top strapping gives strength to the bread mould.

- It maintains an outer dimension of the bread mould and protects box top and sides from impacts during depanning action.

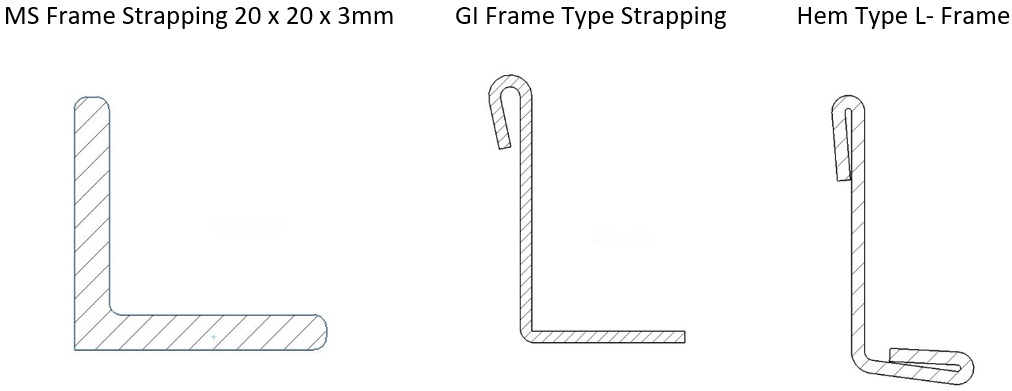

Normally Rolex recommends two types of top strapping sections with 1mm or 1.2mm thickness. Strapping design can be done as per customers’ requirements as well. (Ref Figure 1 round 1).

-

-

Rolex Design

-

Rolex standard design is made up of Galvanized Iron (GI) material with thickness of 1mm or 1.2mm. The sheet metal strip’s two edges are bent and pressed to form a hem. The center is then bent outward to give the strapping a slight C chape is the center.

-

-

- This design is cost effective solution for strapping of bread and rusk mould and is more suitable for bread moulds. (Ref Figure 1 round 1).

- The strap provides exponential strength as compared to the original cut sheet.

-

This not only provides the mould rigidity but also does so with minimal material weight. This keeps the mould light as well as durable.

-

-

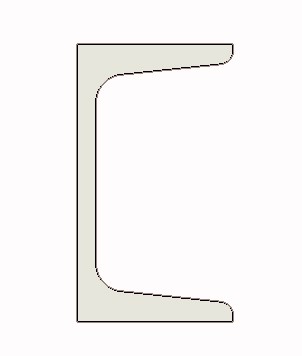

Curled Designs

-

The curled type strapping has it one edge bent in the shape of a “C” to cover the wire frame in the box top. This way the box wire frame gets encompassed in the strapping curl.

-

-

- This design helps in protecting the mould’s top from constant hammering action due to stacking of moulds during storage and also when placing lid on top of the mould.

- Curled type strapping is designed to give protection to the top portion of the bread box above the wire.

- As strapping is curled from one edge, this vastly improves the strength of the mould as compared to other competing strapping design.

-

The material & the strapping properties are similar to the Rolex top strapping. (Ref Figure 2 round 1).

-

-

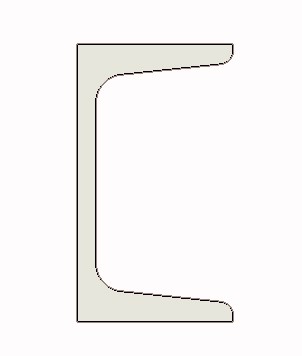

MS Strip & MS C-Channel Strapping

-

MS Strip type strapping is simply a standard MS flat 20x3mm section. And MS C-Channel is the standard available ¾” MS C-Channel. Both these material types are readily available in the market and are used by Rolex upon recommendation from the client. C-channel is welded at the corner as well as directly spot welded to the bread box, it protects the Rim of the side bread box

-

-

- Rolex does not recommend a MS C-channel and /or MS strip as a top strapping,

- Since this material is normally made from scrap steel, the size and material consistency are lacking, hence there is a vast variation in quality and size

- As this material is thick, it increases the weight of the mould without adding a considerable advantage over the Rolex standard strapping design

- The material may rust and after rusting the moulds end up looking dirty and the rusted material may contaminate the food item being baked in it.

- But as per customer requirement we can provide GI C-channel also, which will be the standard 1.2 or 1mm thick GI Strip bent into the form of a C section.

-

Dimensions of the C-channel will be as per customer’s requirement.

-

-

Custom Strapping

-

Strapping can also be designed to meet specific production and machinery design constraints. Right from design to material, everything is customizable as per requirement.

2. Bottom Strapping

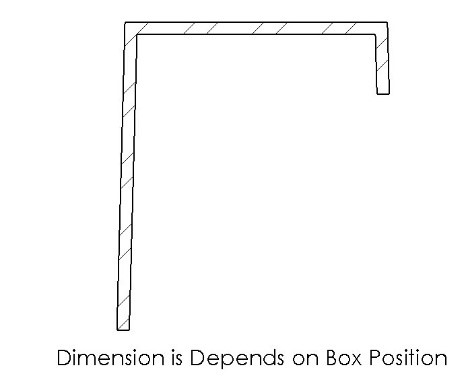

Bottom strapping protects the bottom of the bread mould. Normally bottom strapping is provided 1-2mm lower than bottom of the box to protect the base of the moulds. Rolex use three types of bottom strapping designs with different materials. Strapping design can be done as per customers’ requirements as well. (Ref Figure 1 round 2)

- Normal Type:

Normal type of bottom strapping is similar to the Rolex standard top strapping design. Strapping is spot welded with the box and corners welded. This is the most basic and cost-effective solution for long life of the bread mould. It also ensures the moulds remain light in day-to-day usage and handling.

- Frame Type:

The L-Type frame strapping, as the name suggest is a strapping design which extends and folds onto to the base of the mould, in the form of an “L”.

- It protects the bottom of the mould from significant wear during loading and unloading of mould from tray or trolley.

- This type of strapping is particularly suitable for wood fired ovens, as it raises the mould slightly from the base. This enables the worker to easily slide the wooden lifter to pick and move the mould in and out of the wood fired oven.

Frame type bottom strapping is normally available in both Galvanized Iron and Mild Steel. Mild steel strapping is made by using 3mm thick MS Angles, it is the simplest type of strapping. Mild steel is harder and thicker than galvanized frame type strapping, hence it adds more weight to the mould. GI frame strapping is similar to the mild steel strapping in terms of utility. The only difference being the material and construction, the GI one being much lighter and performing the same role. (Ref Figure 2 round 2).

- Hem Type L-Frame Strapping:

This type of strapping has a hem at the end of the L-frame. The hem increases the strength of L-frame edges. This type of design is only possible in GI Material.

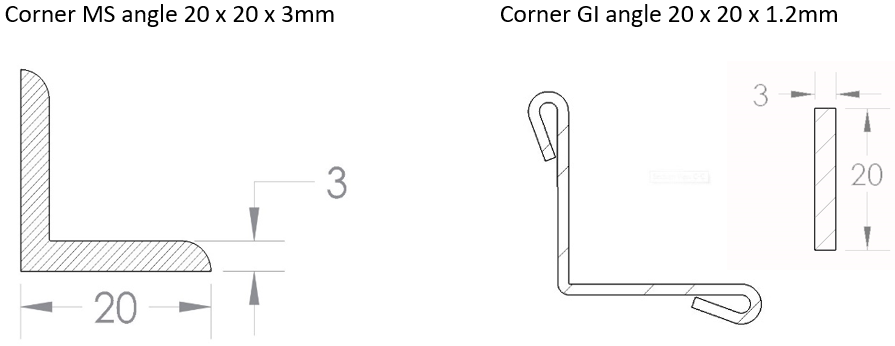

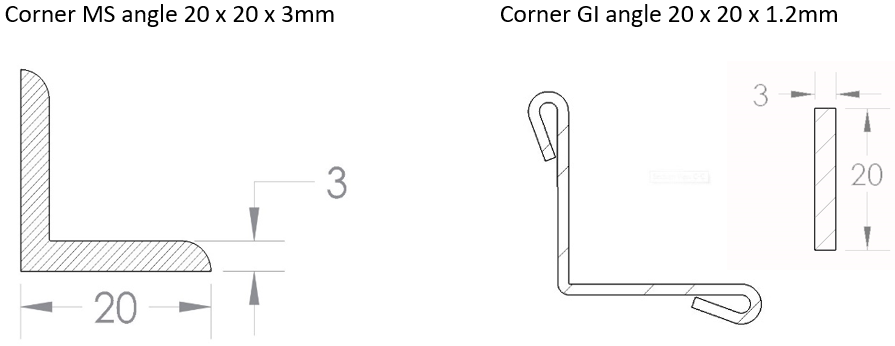

Both the top strapping & the bottom strapping are joined together using angles at the corners and MS supports between the top and bottom straps. Although MS supports are optional and are used for added strength, corner angles are used to not only join the top and bottom strapping adding to the strength of the bread mould wall but it also protects the corners of the set against impacts and collisions. Adding the corner angle is not possible when bottom strapping is not used. Galvanized iron corner angles having 1.2mm thickness and mild steel corner angles having 3mm thickness. (Ref Figure 1 round 3)

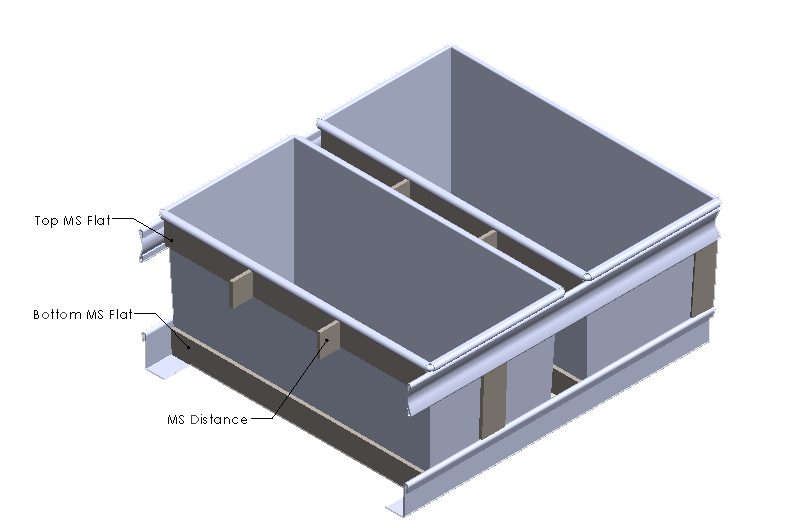

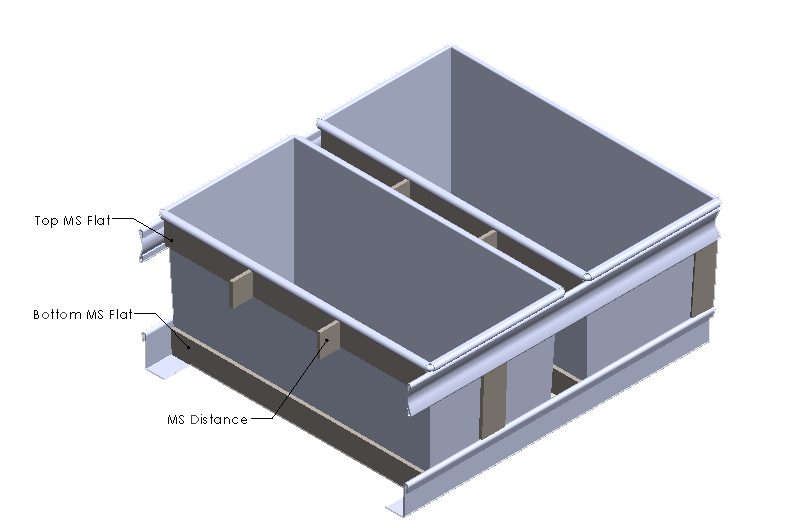

When MS flats are used between the boxes for adding strength and structural support for protection during severe impacts, MS distance may or may not be used. The MS Flats are spot welded to the box and are then welded to the top & bottom strapping to provide superior rigidity & durability. It will give the strength to the whole bread mould set. Normally we use 20 x3mm MS flat, it is best suitable for large bread moulds. Adding MS flats on inside of the mould will also make the mould heavier. (Ref Figure 1 round 4).

MS Distance may or may not be used, it depends on the gap between boxes. Normally it is used when the box is large and the gap is more than 30mm between boxes. MS Distances is used to add more structural strength to the inner walls of the box. We add one or more MS distance per gap between box depending on the length of bread box.. (Ref Figure 1 round 6).

M.S. Supports

M.S. supports are welded between top and bottom strapping of the sets with significant height. They protect the Box wall as well as preventing twisting of bread mould. Both Length Side and breadth side MS supports are available. Multiple supports also can be added based on the size of the moulds and the weight of the bread being baked. They also add to the structural strength of the mould. (Ref Figure 1 round 7).

GI Distance is used between boxes that lack MS flats. GI 1.2mm distances are projections welded to the box wall to support the inner edges under the wire rim.

- GI distances support the boxes in the center and prevent the boxes from getting damaged or bulging during impacts due to de-panning action.

- GI distance clamps add a lot of rigidity to moulds by also keeping its weight light.

They are welded to the wire rim of the box in case the distance between boxes is larger than 20mm making the support very robust and firm.

Bread mould box are fabricated with a 4mm GI wire in top rim. A thicker wire can also be added as per the client’s specific customization.

- GI wire protects the box edge from bending and warping

- The wires are bent in shape of a square “U” and its fork lengths are kept in the ratio of 60-40. This allows for added resistance to warping, without any additional weight. (Ref Figure 1 round 8)

Bread box are provided with a slight tapered bottom. It helps the bread come out easily during depanning. We normally suggest keeping the bottom dimension of the box 5mm less than the top dimension but it can also be changed to suit specific client needs.

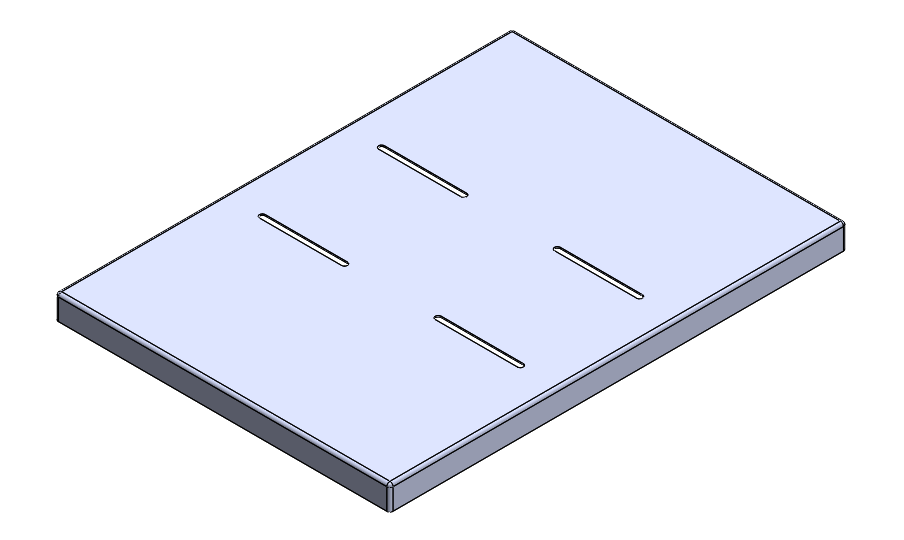

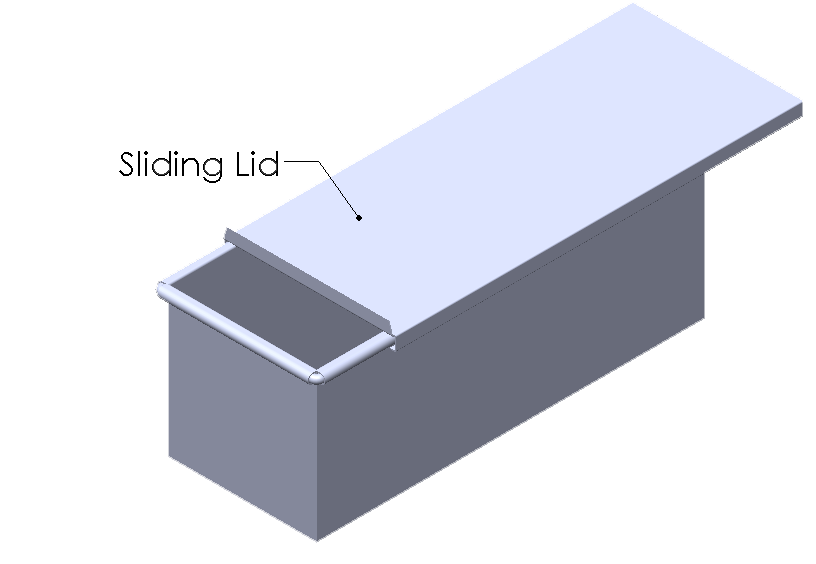

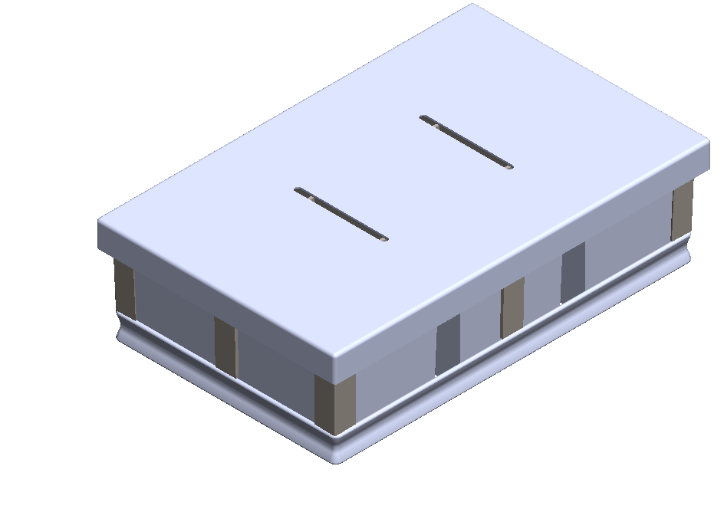

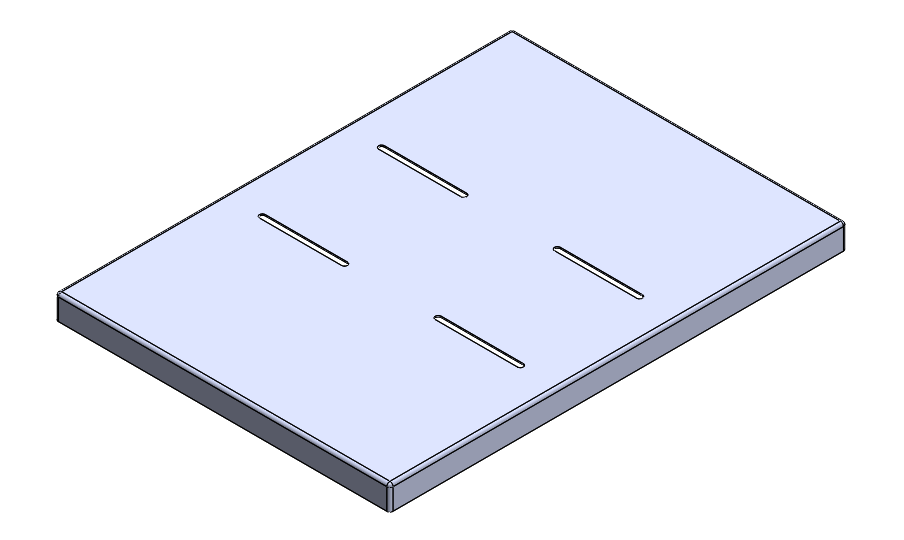

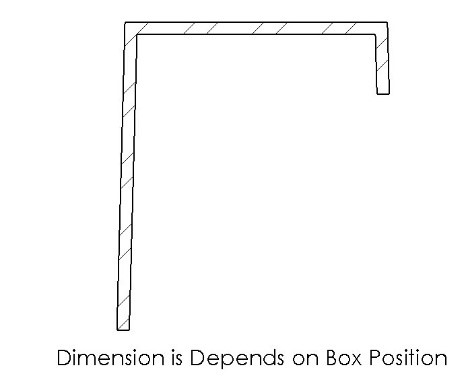

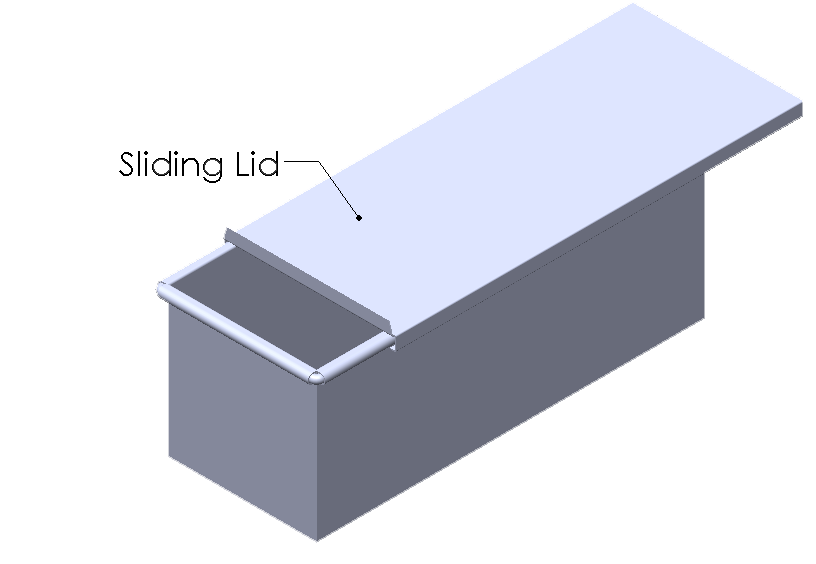

Bread and rusk moulds are provided with lid to maintain consistent shape and size of the baked item. Depending upon the configuration and client requirement, Rolex makes lids of different designs.

- Sliding Lid

This type of lid is made for boxes which are made a single piece, i.e. they are not multi pocket construction. The lid of this type is able to slide on the box wire frame. They are light in construction and are normally made of the same material thickness as the box itself. The design of the lid is such that within its sliding mechanism, it also locks itself in place so that during baking, the dough is not able to lift the lid. This way the bread shape is maintained.

- Drop Lid

This type of lid design is usually used for multi pocket bread and rusk mould. The lid is simple put-on top of the mould before baking. Rolex recommends using Aluminized steel 1.2mm thick for type of lid design. Since this lid is heavier, the weight of the lid itself is enough to ensure the bread is not able to lift it, hence maintaining the shape. Material thickness can be changed as per the client’s specific requirement. This type of lid is provided with capsule cutout which are placed in such a way that they come in between the pockets of the mould, this helps in air circulation during baking and enables an even heating.

Strapping is a sheet metal strip which is folded and pressed on both edges. The strapping is used to hod together the bread box in multi-pocket arrangement.

- They provided solid rigidity to the bread mould set which gives strength against shock, accidental drops and during day-to-day handling.

- Strappings are directly welded to the bread box at the wire corners, hence keeps the boxes secured and prevents them from dislodging during heavy usage and depanning

- Strapping provides support to the top as well as bottom of the set.

- Strappings are customizable to your size and needs.

1. Top Strapping:

Rolex has multiple top strapping designs for the varying needs of consumers.

- Top strapping gives strength to the bread mould.

- It maintains an outer dimension of the bread mould and protects box top and sides from impacts during depanning action.

Normally Rolex recommends two types of top strapping sections with 1mm or 1.2mm thickness. Strapping design can be done as per customers’ requirements as well. (Ref Figure 1 round 1).

-

-

Rolex Design

-

Rolex standard design is made up of Galvanized Iron (GI) material with thickness of 1mm or 1.2mm. The sheet metal strip’s two edges are bent and pressed to form a hem. The center is then bent outward to give the strapping a slight C chape is the center.

-

-

- This design is cost effective solution for strapping of bread and rusk mould and is more suitable for bread moulds. (Ref Figure 1 round 1).

- The strap provides exponential strength as compared to the original cut sheet.

-

This not only provides the mould rigidity but also does so with minimal material weight. This keeps the mould light as well as durable.

-

-

Curled Designs

-

The curled type strapping has it one edge bent in the shape of a “C” to cover the wire frame in the box top. This way the box wire frame gets encompassed in the strapping curl.

-

-

- This design helps in protecting the mould’s top from constant hammering action due to stacking of moulds during storage and also when placing lid on top of the mould.

- Curled type strapping is designed to give protection to the top portion of the bread box above the wire.

- As strapping is curled from one edge, this vastly improves the strength of the mould as compared to other competing strapping design.

-

The material & the strapping properties are similar to the Rolex top strapping. (Ref Figure 2 round 1).

-

-

MS Strip & MS C-Channel Strapping

-

MS Strip type strapping is simply a standard MS flat 20x3mm section. And MS C-Channel is the standard available ¾” MS C-Channel. Both these material types are readily available in the market and are used by Rolex upon recommendation from the client. C-channel is welded at the corner as well as directly spot welded to the bread box, it protects the Rim of the side bread box

-

-

- Rolex does not recommend a MS C-channel and /or MS strip as a top strapping,

- Since this material is normally made from scrap steel, the size and material consistency are lacking, hence there is a vast variation in quality and size

- As this material is thick, it increases the weight of the mould without adding a considerable advantage over the Rolex standard strapping design

- The material may rust and after rusting the moulds end up looking dirty and the rusted material may contaminate the food item being baked in it.

- But as per customer requirement we can provide GI C-channel also, which will be the standard 1.2 or 1mm thick GI Strip bent into the form of a C section.

-

Dimensions of the C-channel will be as per customer’s requirement.

-

-

Custom Strapping

-

Strapping can also be designed to meet specific production and machinery design constraints. Right from design to material, everything is customizable as per requirement.

2. Bottom Strapping

Bottom strapping protects the bottom of the bread mould. Normally bottom strapping is provided 1-2mm lower than bottom of the box to protect the base of the moulds. Rolex use three types of bottom strapping designs with different materials. Strapping design can be done as per customers’ requirements as well. (Ref Figure 1 round 2)

- Normal Type:

Normal type of bottom strapping is similar to the Rolex standard top strapping design. Strapping is spot welded with the box and corners welded. This is the most basic and cost-effective solution for long life of the bread mould. It also ensures the moulds remain light in day-to-day usage and handling.

- Frame Type:

The L-Type frame strapping, as the name suggest is a strapping design which extends and folds onto to the base of the mould, in the form of an “L”.

- It protects the bottom of the mould from significant wear during loading and unloading of mould from tray or trolley.

- This type of strapping is particularly suitable for wood fired ovens, as it raises the mould slightly from the base. This enables the worker to easily slide the wooden lifter to pick and move the mould in and out of the wood fired oven.

Frame type bottom strapping is normally available in both Galvanized Iron and Mild Steel. Mild steel strapping is made by using 3mm thick MS Angles, it is the simplest type of strapping. Mild steel is harder and thicker than galvanized frame type strapping, hence it adds more weight to the mould. GI frame strapping is similar to the mild steel strapping in terms of utility. The only difference being the material and construction, the GI one being much lighter and performing the same role. (Ref Figure 2 round 2).

- Hem Type L-Frame Strapping:

This type of strapping has a hem at the end of the L-frame. The hem increases the strength of L-frame edges. This type of design is only possible in GI Material.

Both the top strapping & the bottom strapping are joined together using angles at the corners and MS supports between the top and bottom straps. Although MS supports are optional and are used for added strength, corner angles are used to not only join the top and bottom strapping adding to the strength of the bread mould wall but it also protects the corners of the set against impacts and collisions. Adding the corner angle is not possible when bottom strapping is not used. Galvanized iron corner angles having 1.2mm thickness and mild steel corner angles having 3mm thickness. (Ref Figure 1 round 3)

When MS flats are used between the boxes for adding strength and structural support for protection during severe impacts, MS distance may or may not be used. The MS Flats are spot welded to the box and are then welded to the top & bottom strapping to provide superior rigidity & durability. It will give the strength to the whole bread mould set. Normally we use 20 x3mm MS flat, it is best suitable for large bread moulds. Adding MS flats on inside of the mould will also make the mould heavier. (Ref Figure 1 round 4).

MS Distance may or may not be used, it depends on the gap between boxes. Normally it is used when the box is large and the gap is more than 30mm between boxes. MS Distances is used to add more structural strength to the inner walls of the box. We add one or more MS distance per gap between box depending on the length of bread box.. (Ref Figure 1 round 6).

M.S. supports are welded between top and bottom strapping of the sets with significant height. They protect the Box wall as well as preventing twisting of bread mould. Both Length Side and breadth side MS supports are available. Multiple supports also can be added based on the size of the moulds and the weight of the bread being baked. They also add to the structural strength of the mould. (Ref Figure 1 round 7).

GI Distance is used between boxes that lack MS flats. GI 1.2mm distances are projections welded to the box wall to support the inner edges under the wire rim.

- GI distances support the boxes in the center and prevent the boxes from getting damaged or bulging during impacts due to de-panning action.

- GI distance clamps add a lot of rigidity to moulds by also keeping its weight light.

They are welded to the wire rim of the box in case the distance between boxes is larger than 20mm making the support very robust and firm.

Bread mould box are fabricated with a 4mm GI wire in top rim. A thicker wire can also be added as per the client’s specific customization.

- GI wire protects the box edge from bending and warping

- The wires are bent in shape of a square “U” and its fork lengths are kept in the ratio of 60-40. This allows for added resistance to warping, without any additional weight. (Ref Figure 1 round 8)

Bread box are provided with a slight tapered bottom. It helps the bread come out easily during depanning. We normally suggest keeping the bottom dimension of the box 5mm less than the top dimension but it can also be changed to suit specific client needs.

Bread and rusk moulds are provided with lid to maintain consistent shape and size of the baked item. Depending upon the configuration and client requirement, Rolex makes lids of different designs.

- Sliding Lid

This type of lid is made for boxes which are made a single piece, i.e. they are not multi pocket construction. The lid of this type is able to slide on the box wire frame. They are light in construction and are normally made of the same material thickness as the box itself. The design of the lid is such that within its sliding mechanism, it also locks itself in place so that during baking, the dough is not able to lift the lid. This way the bread shape is maintained.

- Drop Lid

This type of lid design is usually used for multi pocket bread and rusk mould. The lid is simple put-on top of the mould before baking. Rolex recommends using Aluminized steel 1.2mm thick for type of lid design. Since this lid is heavier, the weight of the lid itself is enough to ensure the bread is not able to lift it, hence maintaining the shape. Material thickness can be changed as per the client’s specific requirement. This type of lid is provided with capsule cutout which are placed in such a way that they come in between the pockets of the mould, this helps in air circulation during baking and enables an even heating.